Alloy 625 (Inconel 625)

Characteristics

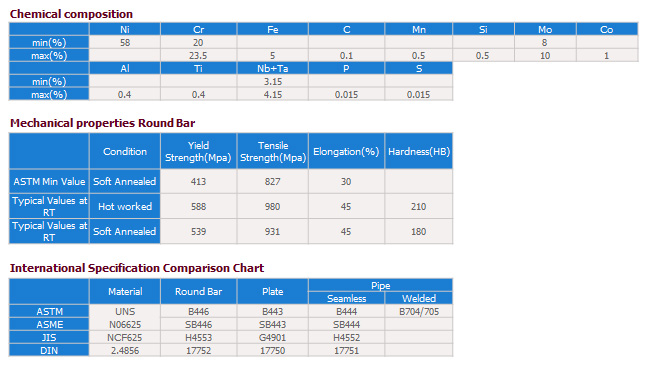

ALLOY625 is a low-carbon Ni-Cr-Mo-Nb alloy which shows excellent resistance to a

variety of corrosive media.

outstanding resistance to pitting, crevice corrosion, erosion and intergranular attack

almost complete freedom from chloride-induced stress-corrosion cracking

good resistance to mineral acids, such as nitric, phosphoric, sulphuric and hydrochloric acids

good resistance to alkalis and organic acids

good mechanical properties

Corrosion resistance

For optimal corrosion resistance the material must be in a clean condition and free from all kinds of contaminants before any fabricated component is placed into service. Under these conditions ALLOY625 exhibits excellent corrosion resistance in a wide variety of media:

The solution-annealed version (grade 2) shows good resistance to many corrosive gas atmospheres:

Applications

The soft-annealed version of Nicrofer 6020 hMo (grade 1) is preferred for applications in the chemical process industry, in marine engineering and in pollution control equipment for environmental protection.

Typical applications are:

superphosphoric acid production equipment

For high-temperature applications, up to approximately 1000 ‹C (1830 ‹F), the solution-annealed version of alloy 625 (grade 2) can be used in accordance to the ASME code for pressure vessels. For design calculations for equipment for use within the temperature range of approximately 500 ?1000 ‹C (930 ? 1830 ‹F) the loss in ductility resulting from prolonged exposure within that temperature range must be kept in mind